We design, build and manufacture turbochargers for performance, commercial and industrial vehicles. Below you can learn more about our how we design our turbochargers and products.

Our Turbo Components

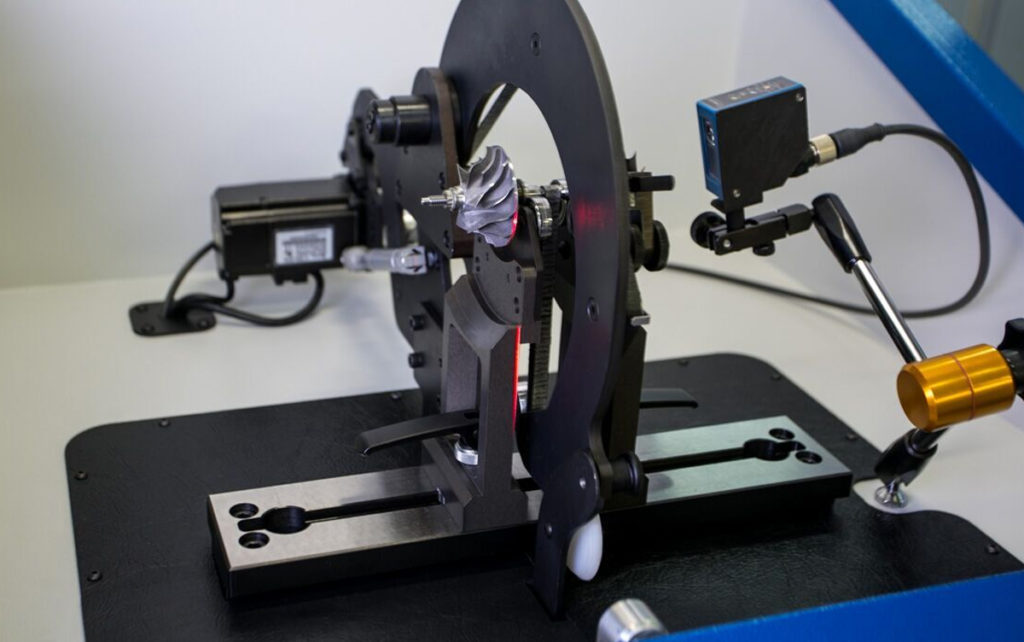

Not only do we fully balance our CHRA, as you have read above, we also balance each of the turbochargers components such as the turbine wheel and compressor wheel. This style of balancing allows each peace to be balanced properly, not only as a complete assembly. This keeps a well maintained product and allows proper air flow to travel correctly.

Our Turbo High Speed Balancing

Building a turbocharger takes a lot more than just assembling pre-made parts together. It takes research, engineering, development, balancing and blue printing the proper sized components.

Our turbochargers are put on a Vibration Sourcing Rig also known as a "VSR" balancer. This gives us the ability to balance our center housing rotating assembly, also known as CHRA, to speeds as high as 300,000rpm. This allows us to correct any and all unbalancing. Allowing your turbocharger to flow steady and operate correctly. Something most companies do not do.

Our Approach

Our Turbo Testing

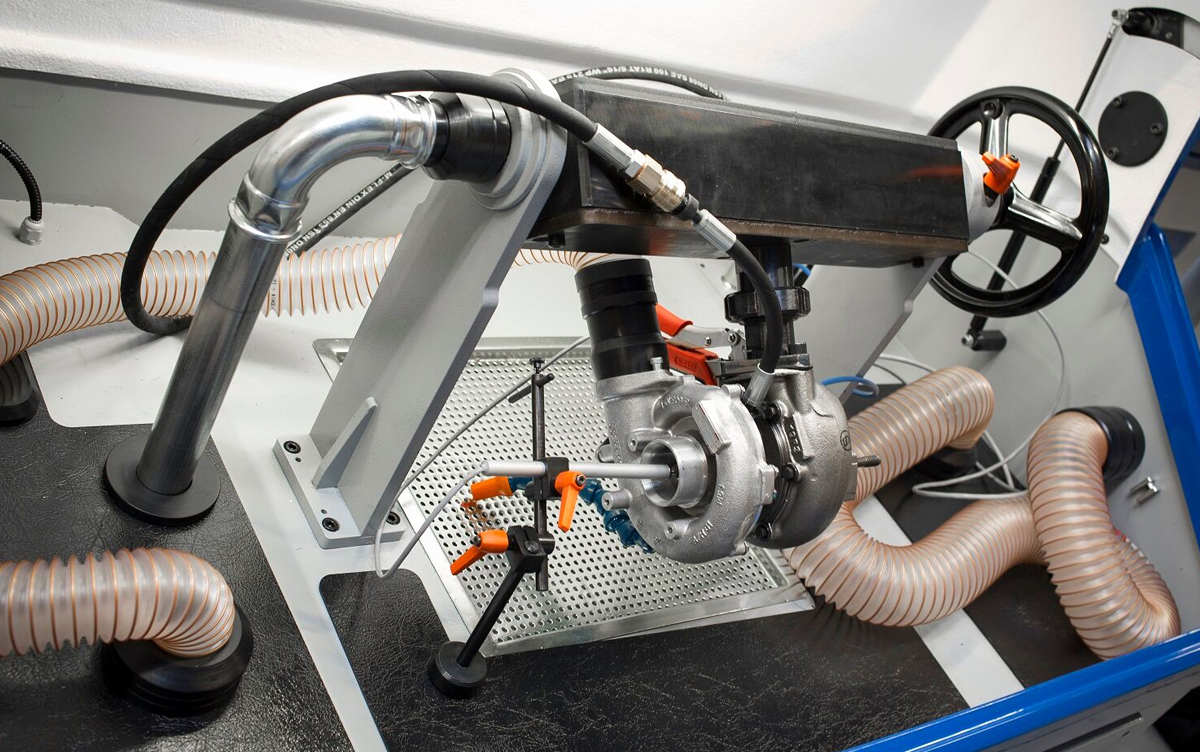

Our calibration flow bench is incredibly accurate, efficient, and allows us to properly flow test each turbochargers compressor outlet airflow, boost pressure airflow, turbo inlets airflow, turbine air flow and all functionality of the turbocharger. This allows us to give our customers a fully functional product.

Another step we take to make sure EVERY turbocharger that leaves our facility is to our standards and performs as advertised.